Articles

By Christian Tavira

Application Engineering & Technical Support Manager - NUTEC

April 12, 2023

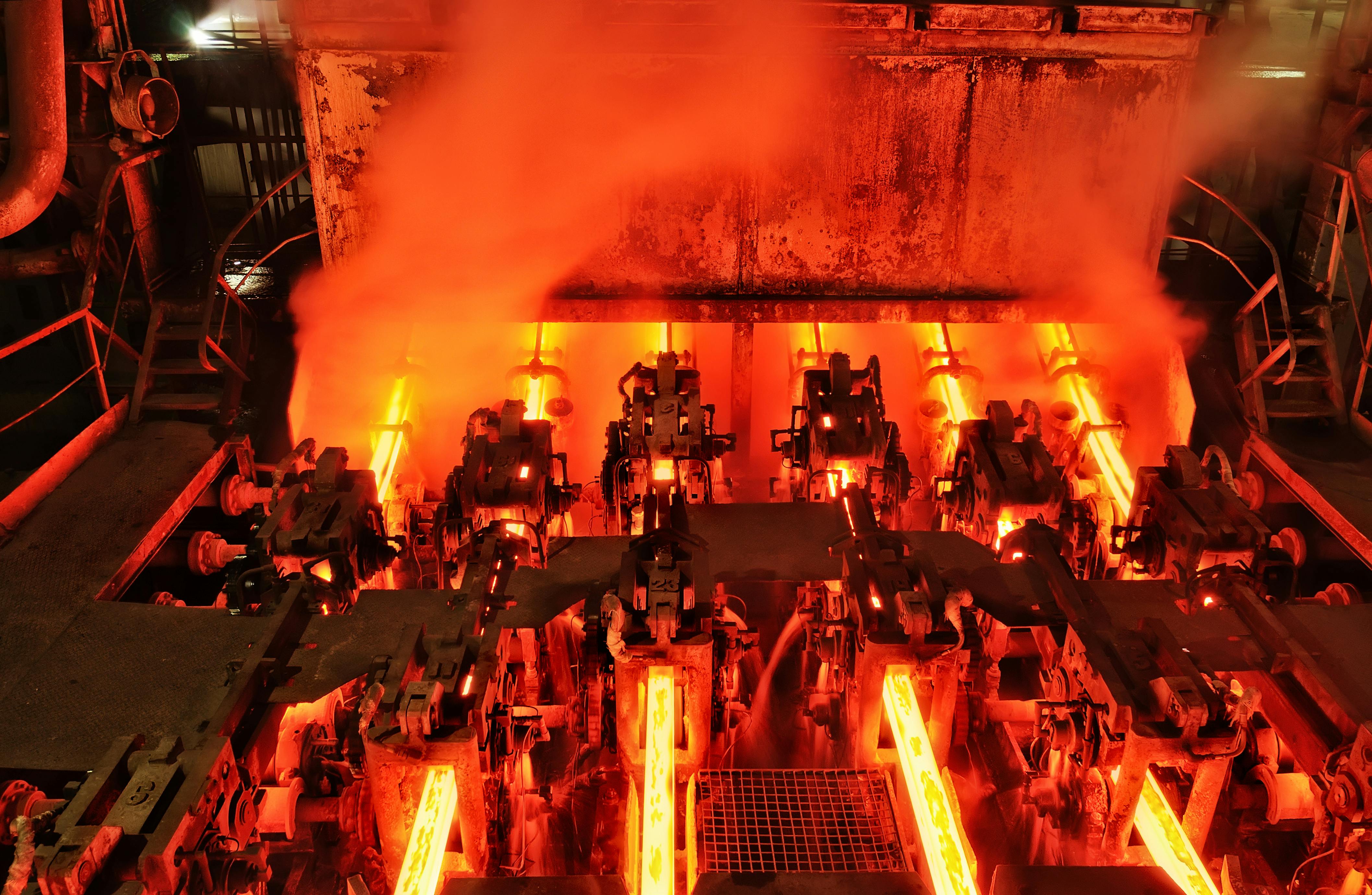

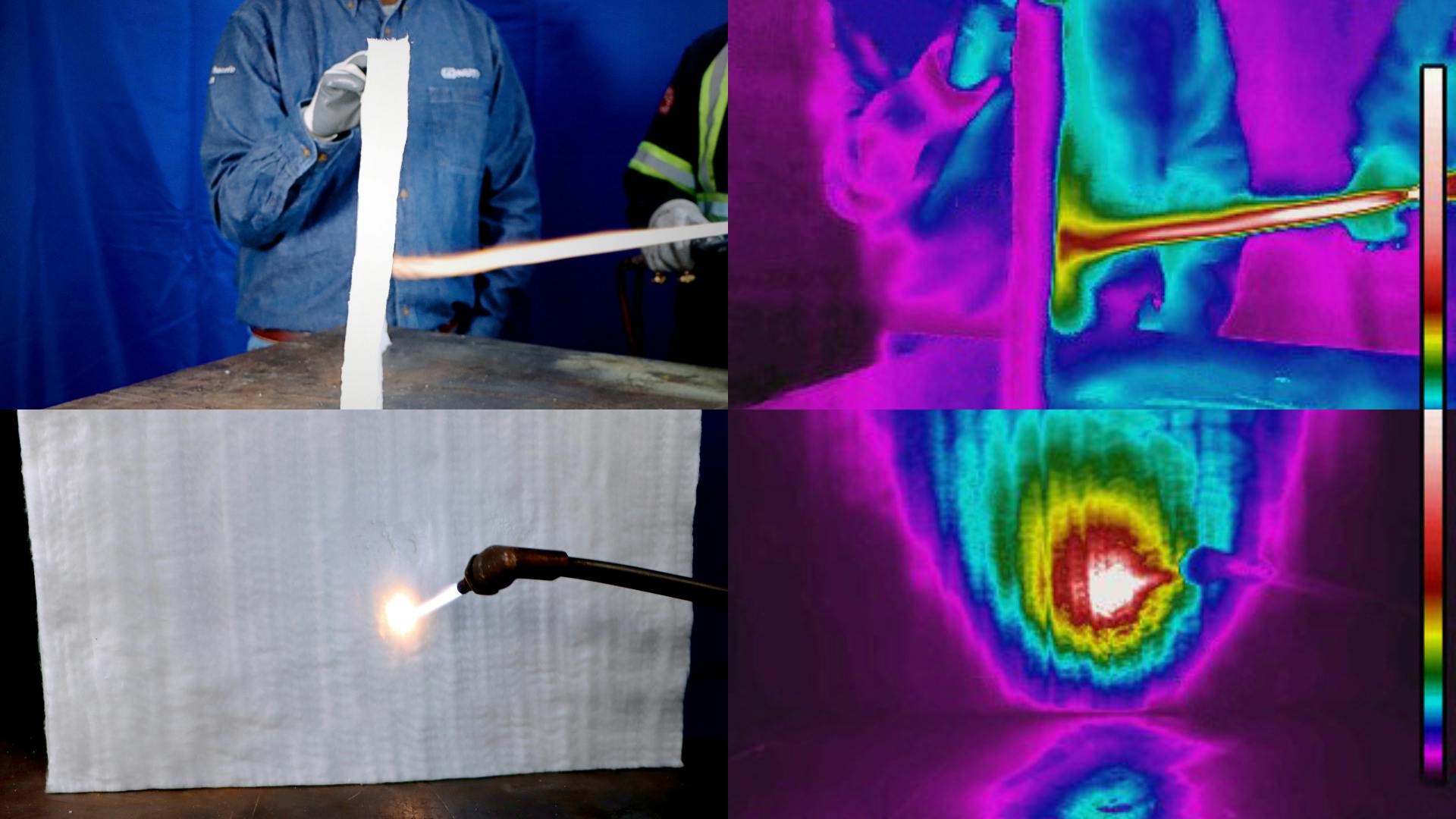

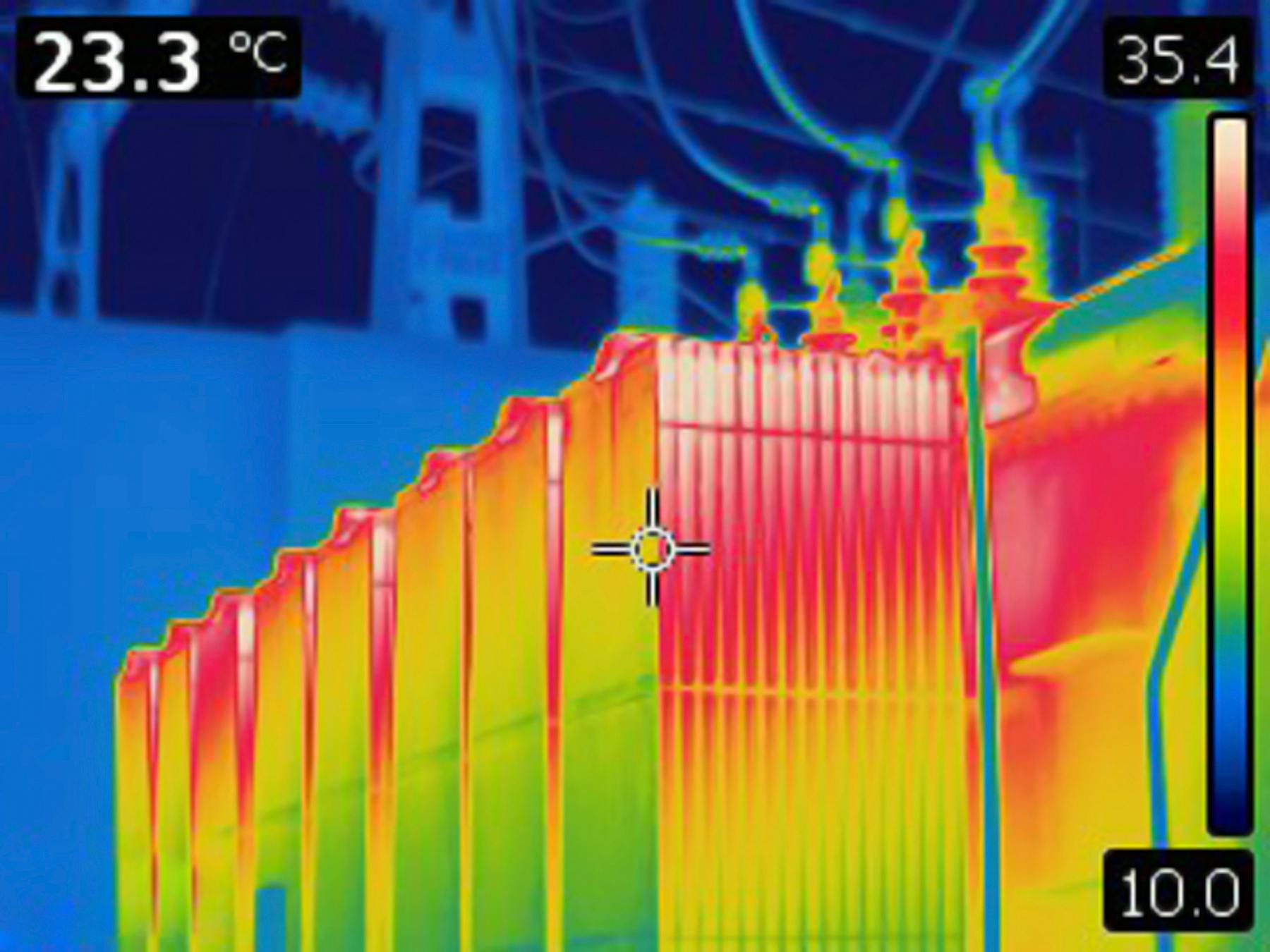

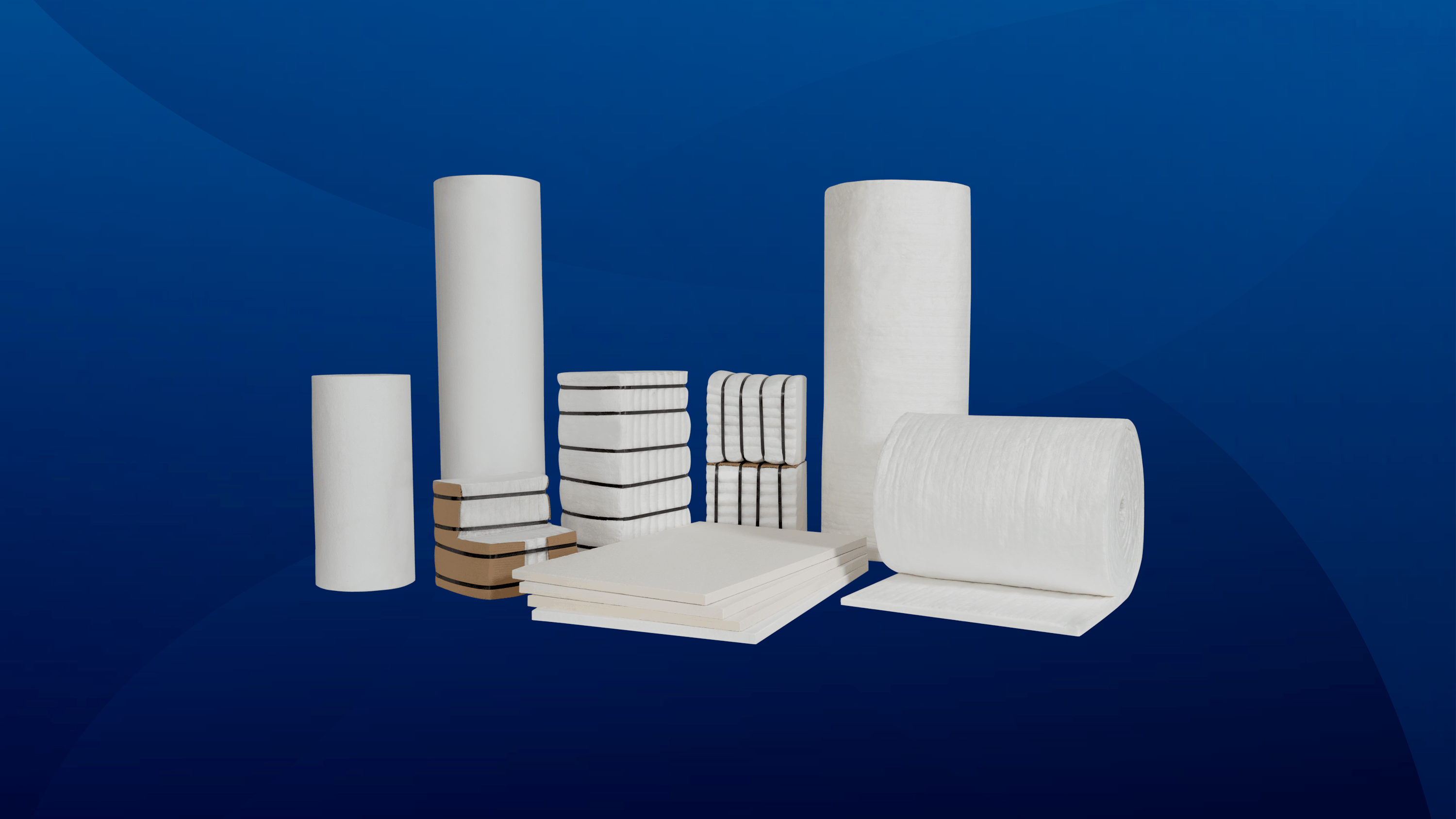

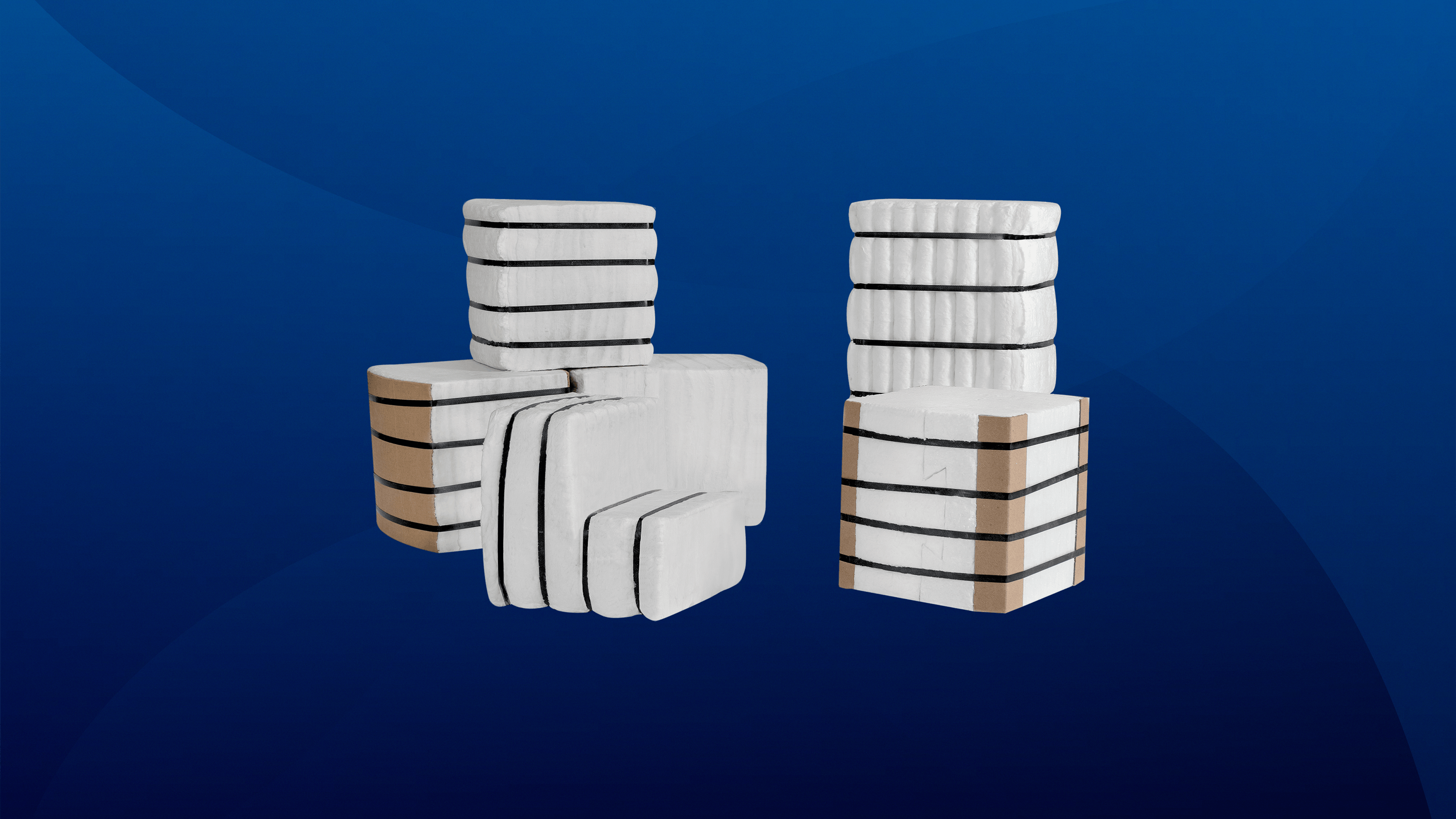

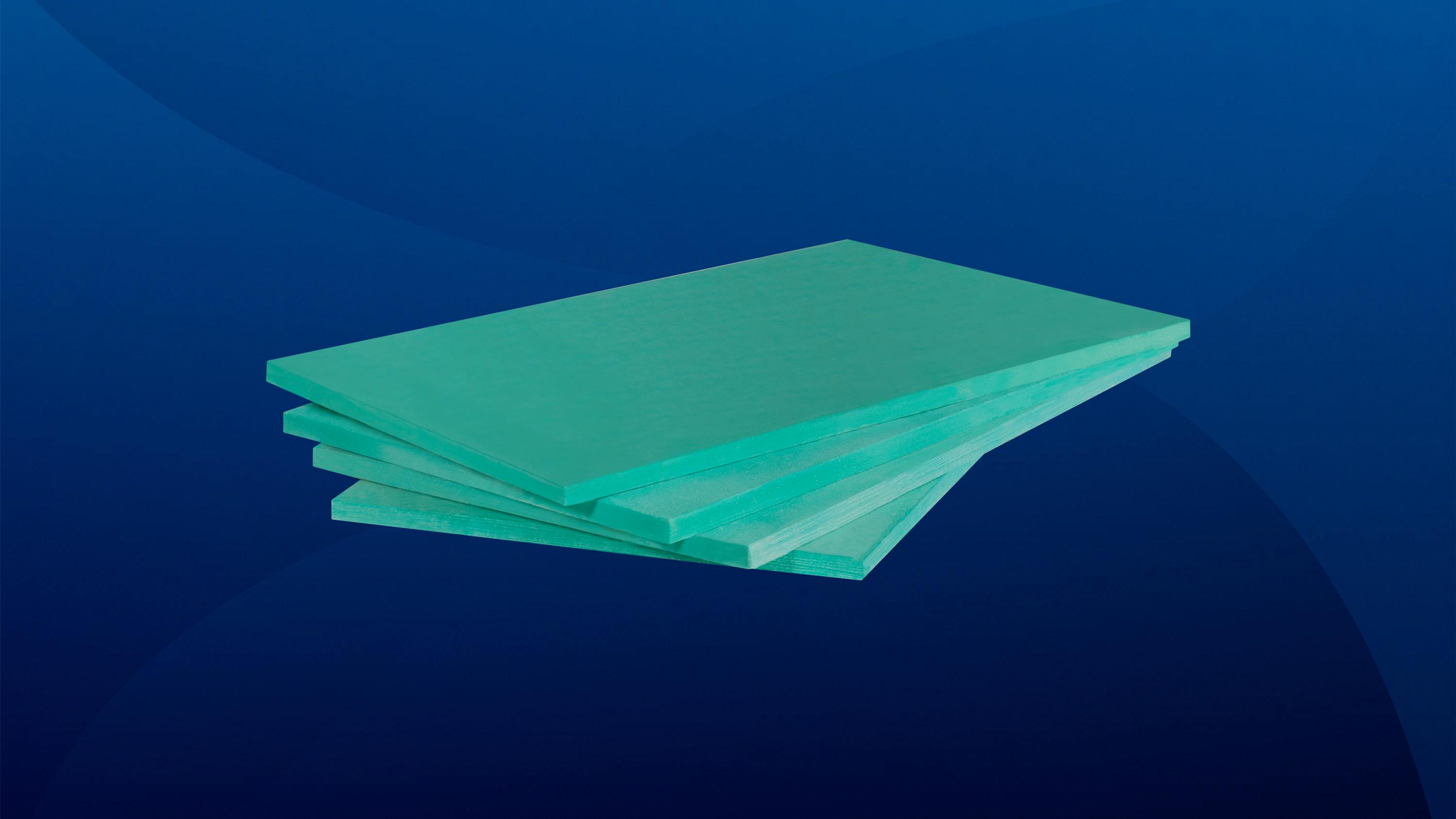

Ceramic Fiber Insulation: Advanced thermal solution for the industrial sector, ideal for high temperature environments. Optimize your insulation today.